Manufacturers use artificial intelligence (AI) by automating, enhancing, and improving production with tools such as machine learning, computer vision, and predictive analytics. Previously used in theory, AI now supports real factory changes.

Why now? Because of Industry 4.0, higher labor costs, and ongoing supply chain problems, AI is no longer just an innovation—it is now needed by businesses. A recent report by PwC finds that AI could boost the global economy by up to $15.7 trillion by 2030, with manufacturing expected to earn a big part of that increase.

In this blog, we’ll look at how AI is bringing new opportunities to manufacturing, starting with less downtime and better ways to control quality, up to allowing predictive maintenance and self-driving equipment. We’ll also look at actual examples, the main advantages, and important future trends that you have to know.

If you are in manufacturing and want to remain competitive, now would be the moment to start embracing AI.

What is Artificial Intelligence in the Context of Manufacturing?

AI in manufacturing means using data and smart processes to improve production, enhance the quality of goods, and automate hard work throughout the manufacturing value chain. AI isn’t only about automation; it also learns from data, grows with additional information, and chooses the best option as things happen.

A system that notices its situation and takes steps to improve its chances of success is what NIST describes as AI. Consequently, such systems can identify possible equipment breakdowns in advance, instantaneously spot issues in products, and automatically change how things are made to keep up with changes in demand.

One should be able to tell AI, Machine Learning (ML), and Automation apart. The tasks in traditional automation are limited by set rules, making it great for jobs that repeat often. ML, which belongs to AI, helps machines understand from data and advance with use. AI covers both areas as well as other uses, like natural language, visual recognition, and decision making.

What stands out about artificial intelligence in manufacturing is not only its task replication, but its assistance to human abilities. AI allows engineers, operators, and managers to study much larger volumes of data quickly, helping them achieve smarter actions, faster interventions, and boost efficiency.

As we use AI more widely in factories, it’s meant to increase productivity by removing guesswork from workers, not to replace them. In this day and age, agility and precision are key to success, and AI is supporting manufacturers in acting ahead of problems.

The Impact of AI on Modern Manufacturing

From the early days of using manual looms to now operating fast, digital factories, manufacturing has developed a great deal. In traditional manufacturing, much of the effort was manual, the methods were fixed, and maintenance work was reactive. Still, this strategy tended to result in inefficient work, sudden interruptions, and difficulty scaling the business.

The fourth industrial revolution, Industry 4.0, greatly depends on AI to support cyber-physical systems, IoT, and intelligent automation in manufacturing. With artificial intelligence, machines in manufacturing can detect, think, and respond on their own. It turns factories into places where improvements can be seen right away, all during the same production process.

The use of AI now solves many problems that businesses have dealt with for years. AI and machine learning in predictive maintenance can cut unplanned downtime by up to half, according to McKinsey. Such systems can spot mistakes with 90% or higher accuracy, decreasing the amount of waste. To solve the global shortage of labor, AI takes on difficult jobs and gives workers important insights in real time.

AI technology in smart factories looks at manufacturing data, predicts demand, adjusts the supply chain, and suggests ways to enhance the design. You might wonder if people actually use it, but industrial magnets such as Siemens, Bosch and GE have already added AI to automate tasks, with help in efficiency, yields and cost reduction.

Both manufacturing and AI are now an integral part of each other’s work. AI is changing more than just production as it grows—it’s changing the way things can work. Manufacturers who want to compete in today’s markets cannot ignore the need for AI.

Also read: What Purpose Do Fairness Measures Serve in AI Product Development?

Key Benefits of Using AI in Manufacturing

Artificial intelligence in manufacturing is bringing about revolutionary gains throughout the production line. Artificial intelligence is improving everything from factory operations to operations related to supply chain logistics. A few of the biggest benefits are noted below.

1. Higher Operations Working Speed

AI helps organizations avoid delays by detecting the main difficulties and better using their resources. For example, smart systems can move production schedules accordingly if machines or supplies are late, ensuring maximum production occurs without anyone needing to intervene.

2. Predictive Maintenance & Reduced Downtime

Rather than react to broken machinery, AI lets machines watch for signs of problems in real time. GE applies AI to keep an eye on its gas turbine machines, which has lowered unplanned downtime by up to 30%.

3. Enhanced Product Quality & Defect Detection

With AI, computer vision can closely observe products in large numbers at a level that exceeds what humans can do. The tech allows Bosch to detect very small problems in vehicle components and maintain steady quality while reducing wastage.

4. Better Demand Forecasting & Inventory Management

Artificial intelligence reviews market developments, customers’ behaviors, and yearly trends to help with demand forecasting. This means you can make better choices about what to stock. An AI tool may enable a consumer electronics firm to avoid creating too many goods in advance of peak shopping periods.

5. Energy Savings & Sustainability

With artificial intelligence, it is now possible to detect losses in energy usage quickly. Smart systems easily turn off unnecessary equipment and control heating and cooling optimization to help drops in both carbon and utility costs.

6. Customization & Production Flexibility

With AI, production can easily change according to the demands or changes found in new orders. Through AI-guided robotics, Adidas’ Speedfactory makes personalized shoes that take less time to make.

7. Workforce Safety & Risk Mitigation

By using their artificial intelligence, robots complete hazardous tasks, while machine learning studies past safety incidents to predict risks. As a result, employees are secure and health and safety incidents are avoided before they even happen.

It is clear from these benefits that manufacturing and AI aren’t only focused on automation—they lead to transformation. Future factories are intelligent, adaptable, and highly flexible—all made possible by AI.

Real-World Applications & Use Cases

AI isn’t a mere theory—it’s already changing the operations of manufacturers. This is a breakdown of how AI is being put to use in different functional areas of manufacturing:

1. Predictive Maintenance

With IoT sensors and machine learning, manufacturers can now tell if a problem is coming before it appears. They assess vibration, temperature, and performance information to spot early warnings. As an example, Siemens saves many millions every year in downtime and repairs by monitoring gas turbines with AI-driven predictive maintenance.

2. Quality Assurance & Defect Detection

Automatic detection of very small defects is possible in these sectors because AI uses computer vision and deep learning functions. An important pharma company adopted AI in imaging tools to spot tiny issues on tablets and guarantee better batches and fewer recalls.

3. Supply Chain & Inventory Optimization

AI helps manufacturing avoid supply problems by accurately forecasting demand using AI. Smart-in-time approaches use real-time information together with limited stock, unlike the just-in-time systems of earlier times. Amazon’s predictive system uses AI to stock its warehouses before customers buy, all based on previous buying trends.

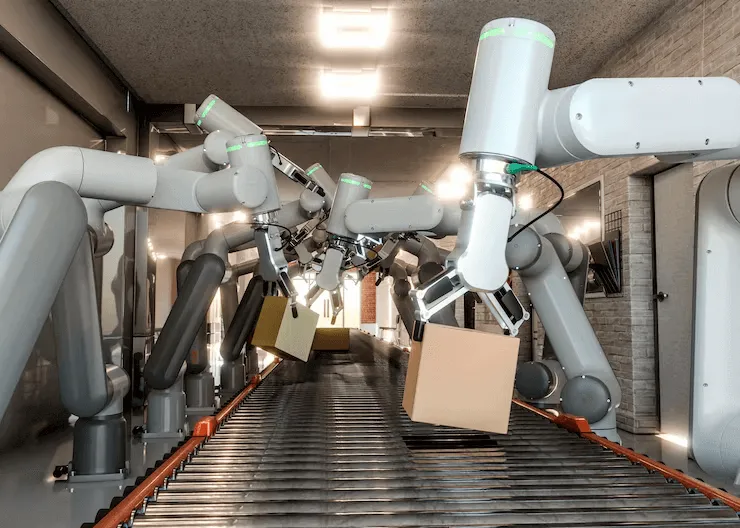

4. Automation Processes and Robotics

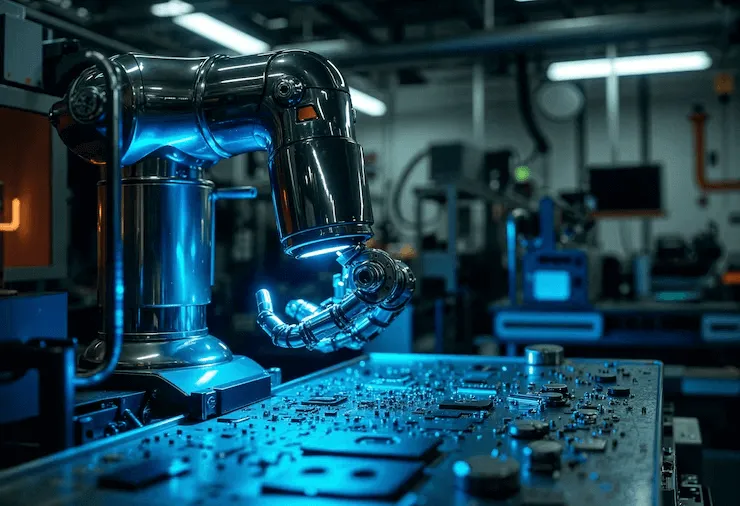

Cobots (collaborative robots) are assisted by AI, so they can interact safely with people, and they don’t need to be reprogrammed much. Unlike conventional robots, they are guided by AI, so they set the right pressure when dealing with fine pieces, making precision manufacturing much more efficient.

5. Energy Saving & Reducing Waste

AI technologies watch energy usage, help save power, and can handle smart grid management. AI plays a part in green manufacturing by sorting recyclable things and decreasing the waste produced. Schneider Electric relies on AI to control energy usage in factories and thus lower emissions and raise efficiency.

6. Ensuring Safety At Work & Teaming With Machines

AI wearables watch key signs and the environment, warning workers if a problem is growing. In the coming years, we can foresee machines taking on risky tasks while humans concentrate on new inventions and supervision.

These examples point out that AI isn’t only updating manufacturing, but it is truly transforming it.

AI Tools and Technologies Powering Manufacturing

The industry’s transition to digital is backed by a powerful collection of AI tools. As a result of using these tools, smart choices, automation, and instant analytics are defining the future of AI in manufacturing.

Key Technologies Driving AI in Manufacturing:

- At the core of AI in manufacturing, Machine Learning (ML) improves operations by learning from past and real-time data, for example, by telling when equipment is likely to fail or adjusting production steps.

- In quality control, Computer Vision helps machines notice problems by analyzing what they can see, giving organizations added accuracy in their operations.

- A Digital Twin is a computer-generated image of a real asset that helps plan, test, and improve its working performance before it is put into real use.

- Through IoT sensors, huge amounts of data are collected by the system, which AI uses for making predictions about operations, energy use, and repairs.

- In roles where communicating with clients is key, NLP lets machines interpret and produce language that simplifies tasks such as planning and reporting issues.

How Real-World Platforms Are Used

A number of AI platforms are helping manufacturing by integrating AI.

- Siemens MindSphere gathers data from the world of industry using AI and analytics to improve production.

- IBM Watson for IoT gives companies the ability to learn from connected gadgets and use AI in their processes.

- GE Predix is concentrated on maintaining equipment before major failures happen and on digital representations of physical systems in industry.

Companies in manufacturing may either decide on open-source tools (for flexibility and creativity) like TensorFlow or PyTorch, or use proprietary systems for the ability to scale up and be well-supported. You need to decide based on how complicated, large, and secure the software or operation needs to be.

With changes in these technologies, AI’s usefulness in industrial automation also grows.

Also read: Artificial Intelligence (AI) in Everyday Life

Industry-Specific Examples

Every manufacturer sees different effects from AI. Each industry is using artificial intelligence to solve important problems, get more done, and encourage new ways of thinking. AI is redefining the main areas of manufacturing.

Automotive: Automated Inspection and Predictive Quality Checking

Inspections in the automotive industry are now being transformed by AI applied to industrial automation. Automated paint finish, weld seam, and body alignment inspections are possible with AI-equipped computer vision systems. Major companies such as BMW use AI to detect risks to quality and make improvements ahead of time.

Aerospace: Component Reliability Prediction

Because safety and accuracy are so vital, artificial intelligence is used by aerospace manufacturers to predict the performance of primary components. Examining history, use, and patterns, AI allows for a more accurate schedule of spare parts and maintenance needed and helps avoid accidents while ensuring maximum availability.

Electronics: Circuit Board Defect Analysis

In making electronic products, AI-based vision systems help examine circuit boards by detecting very small mistakes that are not noticeable to people. Within 6s, this method helps produce better quality and inspect items much faster.

Food & Beverage: Supply Chain Traceability

It’s possible for food producers to monitor ingredients from where they begin right up to the time they reach shelves. The software monitors information like temperature, supply chain processes, and data from suppliers to secure products and gain consumers’ confidence.

Pharmaceuticals: Preparing and Research & Development

Using AI, drug development is performed faster, as AI analyses huge sets of data to discover good candidates. AI helps make drugs more effective and easier to make. As an example, Pfizer relies on AI to boost its vaccine development and cut down on the time it takes to get the vaccine to patients.

Such industry-specific situations show how flexible and valuable AI is in manufacturing, whether production is precise or done on a large scale.

Challenges and Ethical Considerations

There are significant reasons to use AI in manufacturing, but it’s not always an easy process to fully implement. Those who make, design, and build systems need to focus on technical, ethical, and regulatory issues to implement artificial intelligence sustainably.

Data Privacy and Cybersecurity Risks

Since AI for industrial automation needs data in real time, making that data secure is very important. Vulnerabilities found in IoT technology and cloud-based systems open the door to incidents of intellectual property being stolen, dangerous attacks on computer systems, or privacy being violated. Setting in place strong cybersecurity systems helps to keep both systems and data protected.

Implementation Cost and Skills Gap

Putting together hardware, software, and infrastructure for AI can be too expensive for small to mid-sized manufacturers. There is also a major issue with talent, as facilities aren’t able to acquire the data science or AI engineering skills they need.

Bias in AI Decision-Making

Video surveillance systems can develop flaws and produce unfair results if the data they use is biased. In manufacturing, AI and other applications such as defect detection or hiring workers, skewed data may cause the system to give wrong results or introduce bias. A model must be audited and clear so that all parties are given a fair chance.

Workforce Displacement vs. Upskilling

Most people are concerned about losing their jobs as a result of automation. Though AI may switch roles for some employees, it allows others to help with supervision, data, and AI systems. With these new roles emerging, people will need programs to help them upskill instead of getting left behind.

Compliance and Regulations

Sticking to changing global laws about AI, data protection, and work safety is another problem. Manufacturers need to obey the EU AI Act or ISO standards to avoid negative legal and public image outcomes.

Caring about these concerns is very important to have AI in manufacturing to be responsible as well as powerful.

Also read: Machine learning and Artificial Intelligence’s Effects on Software Development

The Future of AI in Manufacturing

AI in manufacturing is set to change even more, thanks to generative AI, hyper automation, and systems that can learn on their own. Because of generative AI, engineers can already simulate and test models, produce perfect prototypes, and speed up the development process on their computers without creating a physical sample first.

Hyper automation, which means automating every process that can be, is increasing in popularity. They will be able to carry out work and also check, review, and enhance it by themselves. These systems are thought to move factories towards complete autonomy, with decisions being made effectively on the spot, always and automatically.

A McKinsey study predicts that AI might boost the productivity of manufacturing by as much as 40% during the next decade. Deloitte also thinks that within the next ten years, over half of manufacturers will be using AI to predict outcomes and automate workflows.

In the years to come, artificial intelligence in manufacturing will be used not only to help work processes but also to support major company strategies, encouraging innovation, making things greener, and helping the company thrive globally. Early investment in AI technology will help companies become leaders in developing intelligent factories of the future as manufacturing and AI come together.

How to Get Started with AI in Your Manufacturing Process

You should begin by identifying which difficulties you experience in manufacturing, such as stalled machines, poor quality, or managing inventory. After that, collect the important data needed from your activities, since AI needs quality data to give you useful insights.

Deciding on the right AI tools is very important. SMEs can use simple, flexible services, but companies of all sizes can find options that meet their specific business needs. Developing your teams is important, just like helping them build AI knowledge and an innovative environment.

It’s a good idea to run a pilot project for AI to see if it works before applying it more broadly. Review the outcomes, make adjustments to your methods, and then apply proven solutions across your enterprise.

Allowing your company to benefit from AI experts allows for fast implementation and custom solutions designed for your factory’s needs.

If you are either a local business or a large manufacturer, the right steps and alliances are essential to benefit from manufacturing and AI.

Conclusion

Manufacturing companies are changing their ways due to AI, resulting in higher efficiency, precision, and fresh advances across the industry. Enterprises in manufacturing need AI not just because it’s popular, but because it is a critical part of their strategies.

AI is transforming manufacturing, making factories more intelligent, supply chains more streamlined, and making operations prepared for the future. With everything moving online, the time for AI in manufacturing is now.

It doesn’t matter if you want to see technology in application, on a larger scale, or how it shapes the supply chain—the time to embrace it is in everyday life. Would you like to know more about investing? What is the true cost of building AI today?

Start small. Scale smart. Intelligent manufacturing begins with something you should start today.